Engineering the face of cosmetics

Adam Dove

Feb 21, 2020

Every day, millions of people around the world look in the mirror, open their eyes wide, and brush mascara onto their lashes. For many of these people, picking up the tube and painting their lashes is an unconscious part of their daily routine.

But to a chemical engineer, mascara is anything but commonplace—it’s carbon black and iron oxide, with a polymer to form a film that coats the lashes, combined with preservatives and thickening waxes such as lanolin, mineral oil, paraffin, petrolatum, castor oil, carnauba or candelilla wax. That’s because, without chemical engineers, mascara wouldn’t be the incredible product that it is today.

I wanted to create something that really made a difference in the user’s quality of life.

Prashansa Desai, Senior Chemist, L'Oréal

Chemical engineers and chemists are responsible for the vast majority of products we use every day, from the paint on our walls, to the gas in our cars—to makeup and personal care products. Chemists and chemical engineers are important in the cosmetics and personal care industry, innovating the chemical formulations that make lipsticks last, mascaras waterproof, and lotions hydrating. And when cosmetics companies are looking for world-class chemists and chemical engineers for formulating cosmetics, they turn to Carnegie Mellon’s Colloids, Polymers and Surfaces (CPS) program.

“Cosmetics are composed of many ingredients,” says Annette Jacobson, teaching professor of chemical engineering and Director of the CPS program. “These ingredients include colloids, which are very fine particles such as pigments; polymers, which are large molecules that help disperse the pigment or provide important properties to the product; and surfaces, created at the interfaces between these fine particles and the liquids they are dispersed into. Colloids and polymers are combined in unique ways to create cosmetics, but if they don’t spread and adhere properly to the intended surface—in this case, your face or skin—then they aren’t worth very much at all.”

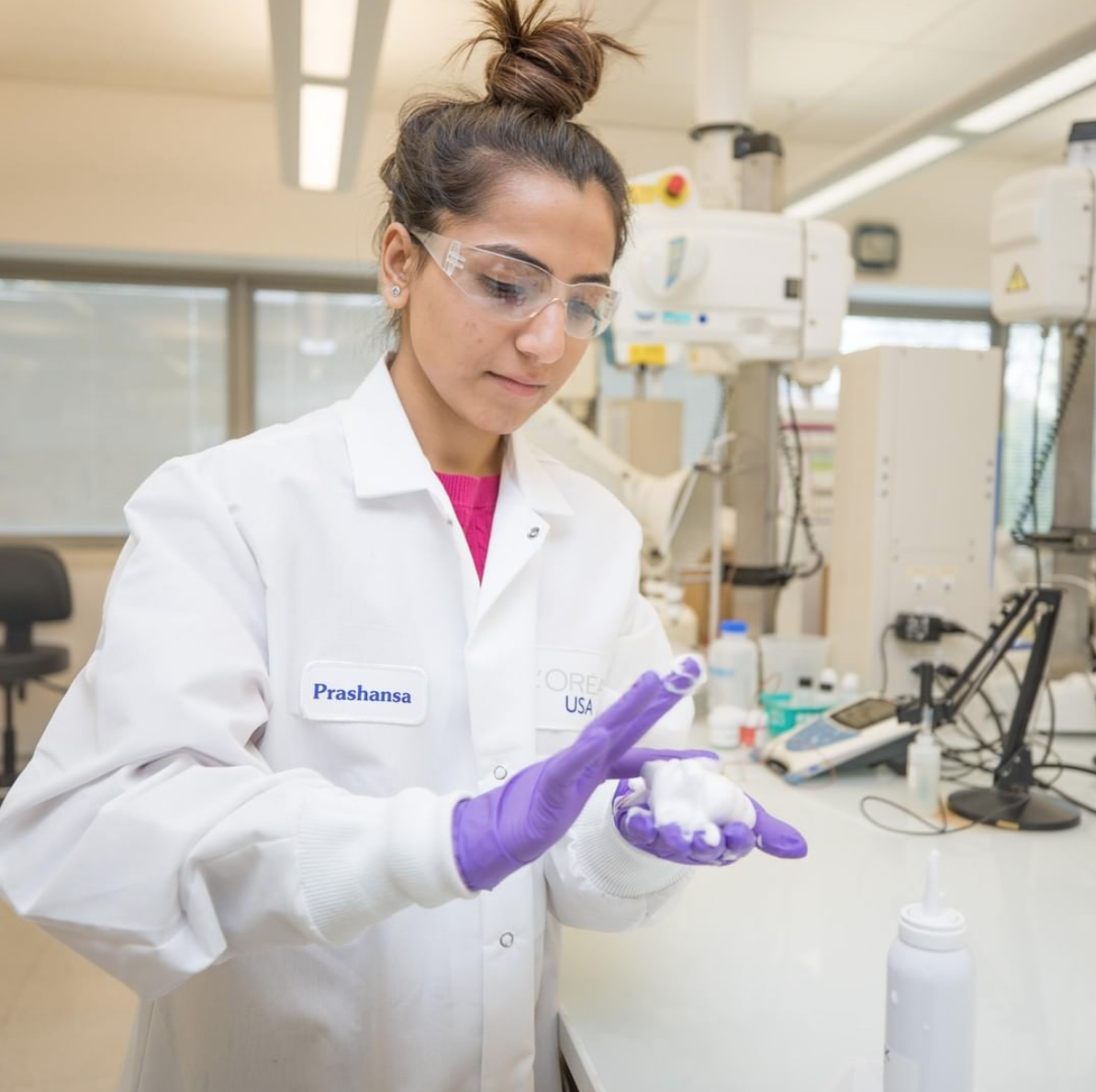

Source: L'Oréal

CPS alumna Prashansa Desai testing hair mousse in the lab.

This emphasis on understanding the surface or interfacial side of things is unique to Carnegie Mellon’s CPS program, and the reason that many graduates find themselves with job opportunities at companies in the cosmetics and personal care industry. Prashansa Desai, who graduated from the program in 2014, now works on the Hair Care and Styling Team at L'Oréal, where she creates new and exciting products, investigates novel ingredients, and experiments in the lab to come up with innovative hair care and styling formulas, which she then tests on actual hair to evaluate its performance.

“I was always fascinated by the chemistry behind the products we use in our daily lives,” says Prashansa. “So I started looking into the ingredients of the products I use, and studying their interactions at molecular level. And soon, I wanted to create something that really made a difference in the user’s quality of life.”

According to Prashansa, her time in the CPS program was an integral stepping stone that helped her get into the industry. Because of the program’s balance of hands-on experimentation and theoretical study, she was able to spend a good fraction of her time in the lab, playing with the practical applications of the concepts she was learning in the classroom.

“For anyone hoping to build a future in the cosmetics industry,” Prashansa says, “Though you can learn to formulate on the job, you must be sure to have your chemistry base clear and strong. Be passionate about creating new products, and develop an acute inquisitiveness. Start questioning everything you see. Take the research-oriented approach. And lastly, don’t be frustrated by trial and error.”

Graduates from the CPS Program have had internships and full-time employment at companies such as L'Oréal, Estee Lauder, Procter & Gamble, Reckitt Benckiser (Lysol), Johnson & Johnson, Merck and PPG.