Maximizing circularity in plastics supply chains

Lauren Smith

Jul 21, 2025

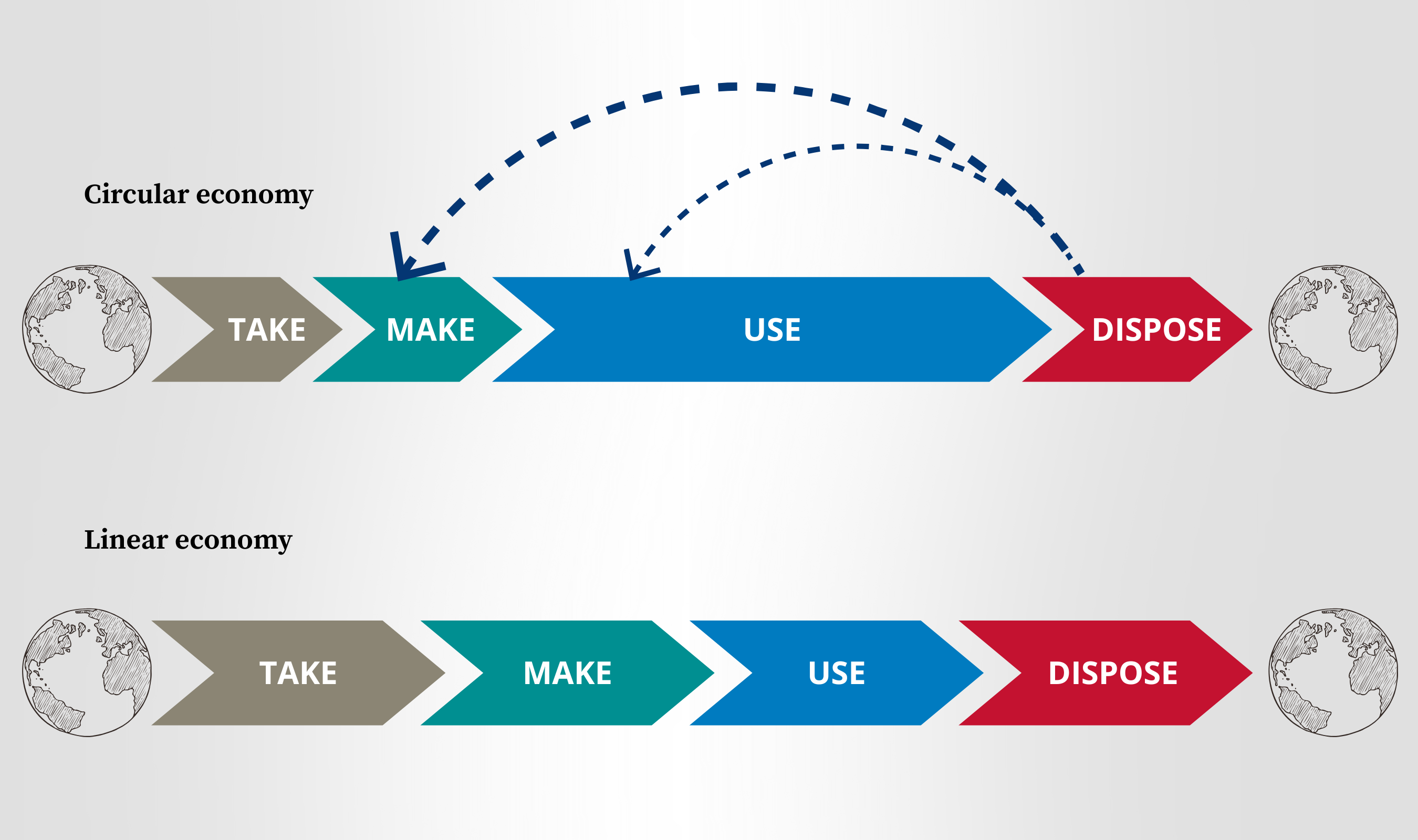

A traditional economy follows a linear "take-make-use-dispose" path. A circular economy, in contrast, retains the value of materials and products within a supply chain for longer.

Industry and policymakers are considering circular economy networks to achieve sustainability goals. Ana Inés Torres is creating systematic ways to help them make decisions with less ambiguity.

"In a circular economy, the idea is to use as much as possible of a product first," explains Torres, associate professor of chemical engineering. "Then, at the end of the product life, we incorporate the product or its components back into different parts of the supply chain."

The Torres Research Group uses mathematical models to design better systems. Recent papers propose frameworks for designing circular economy networks and apply these frameworks to the polyethylene terephthalate (PET) supply chain in the US.

PET is one of the most common plastics in the US, used in water bottles, clamshell packaging, and textiles, among other products. Although it is easy to recycle, most PET in the US ends up in landfills, presenting a clear opportunity for improved circularity.

In Computers & Chemical Engineering, Torres and Abdulhakeem Ahmed propose a framework for designing and optimizing circular economy networks when decision-making involves multiple criteria. They assessed cost, greenhouse gas emissions, and raw material consumption (as a measure of circularity). Torres and Ahmed, a chemical engineering Ph.D. student, determined the optimal recycling process for each objective individually and also evaluated the trade-offs between competing objectives.

Their analysis shows that designing for a circular economy supply chain from the start is more economical and better for the environment in the long term than designing for a linear economy.

Using PET as a case study, Torres and Ahmed conducted a techno-economic analysis of a fully circular economy for PET, in comparison with the traditional linear economy. They looked at possible production, utilization, disposal, and recycling pathways for PET.

Mechanical recycling methods, which are the most common, don't change the chemical composition of the plastic. Chemical recycling technologies use solvents and chemicals to change the composition of plastics waste, such as by separating polymers from additives. The resulting raw materials can be used to make more plastics and other products. Torres and Ahmed show that a combination of mechanical and chemical recycling is the best choice for economic and emissions objectives. For maximizing circularity, chemical recycling is optimal.

"To get to effective solutions for circularity, a lot of different people need to agree," says Ahmed. "What might be optimal for a central system might not be optimal for every individual actor."

The Torres Research Group is also working on methods to analyze systems at the actor level. In Industrial & Engineering Chemistry Research, Torres and Daniel Pert use a system dynamics approach to develop a modular framework for modeling circular economy networks. From their generic model, they derive specific models for five actors (a manufacturer, consumer, material recovery facility, recycling facility, and the Earth) and combine them to form a prototypical circular supply chain network.

Source: Daniel Pert

"We're trying to figure out how the system behaves if each actor pursues their own objectives," says Pert, a chemical engineering Ph.D. student. In a circular economy, decisions made by one actor affect the operations of upstream and downstream actors. Torres and Pert's framework can be used to study these effects over the long-term.

Most circular economy analytical frameworks are based on steady-state models. Analyzing the system at a static level, however, does not account for long-term benefits that may follow short-term costs. By incorporating the time dimension into their framework, Torres and Pert show how variations over time can lead to different outcomes.

They apply their framework to compare the long-term effects of different circular economy initiatives on the supply chain for single-use PET bottles and reusable PET clamshell packaging.

By simulating different scenarios within the existing infrastructure, Torres and Pert show that "slow-down-the-loop" initiatives such as product reuse improve circularity and minimize environmental impact more than "close-the-loop" initiatives such as increased recycling.

The work from the Torres Research Group can help industry and policymakers determine the best pathways and processes for implementing circular supply chains. They can also generalize their methods to other problems, including the recovery of rare earth elements.

For media inquiries, please contact Lauren Smith at lsmith2@andrew.cmu.edu.