Process systems engineering

As we advance the area of systems engineering, our goal is to develop new mathematical models and computational capabilities in:

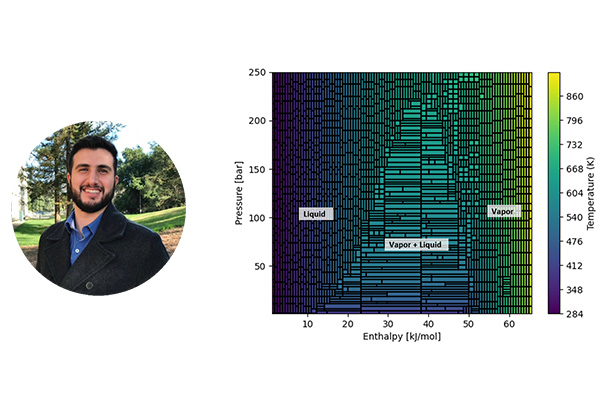

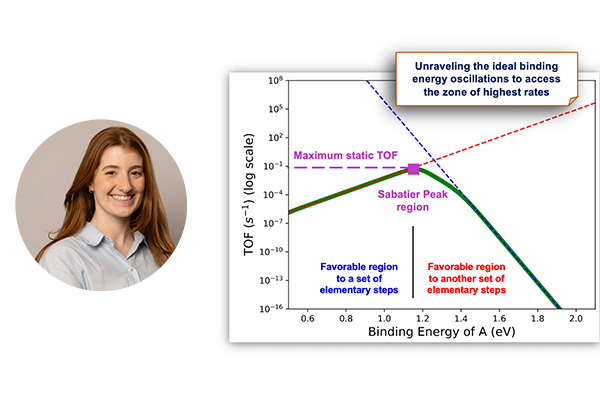

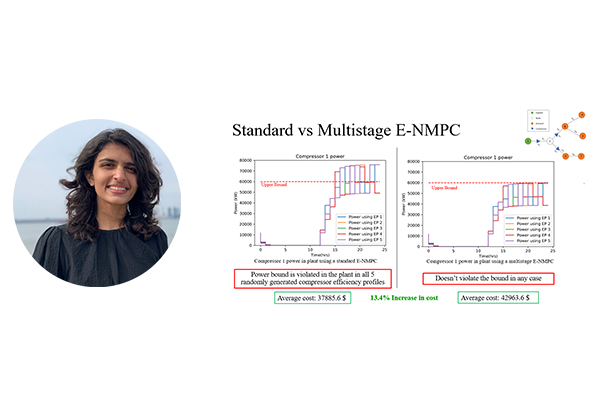

- large-scale nonlinear and dynamic optimization

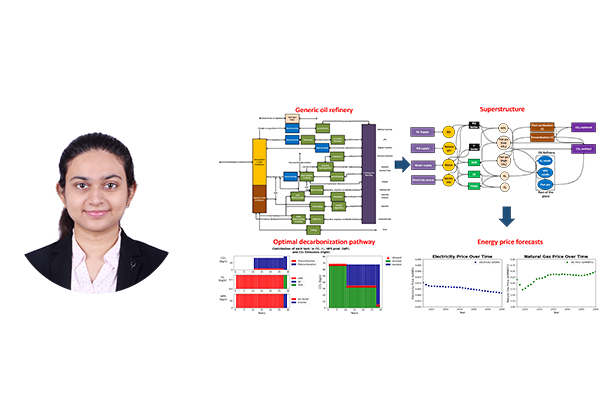

- mixed-integer linear and nonlinear optimization

- optimization under uncertainty (stochastic, robust)

- high-performance and scientific computing

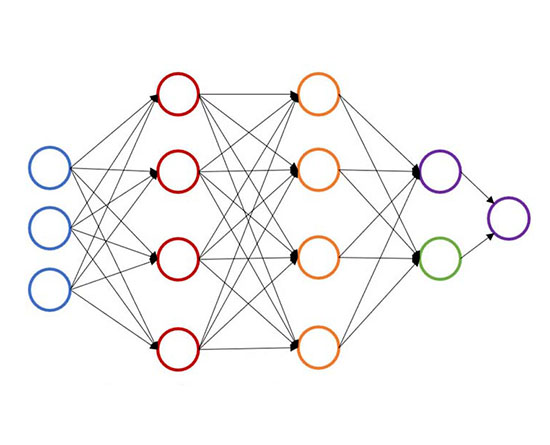

- machine learning and data science

Examples of current application areas include:

- optimal process synthesis, design, operations, and control

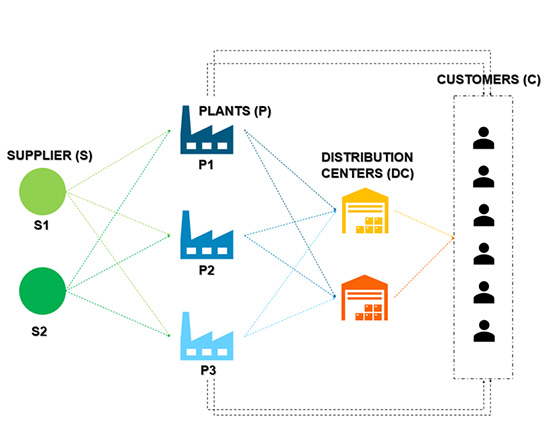

- supply chain, scheduling, planning, and enterprise-wide optimization

- sustainable processes and circular economies

- carbon capture and climate change

- energy systems, renewables, and critical infrastructure

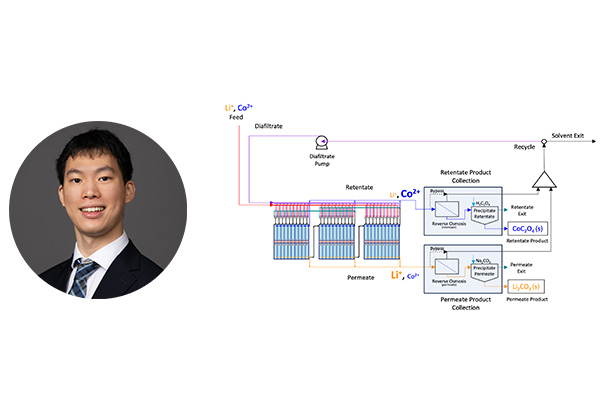

- recovery of rare-earth elements and critical minerals

- materials design and optimization

Sample research projects

Process systems engineering faculty

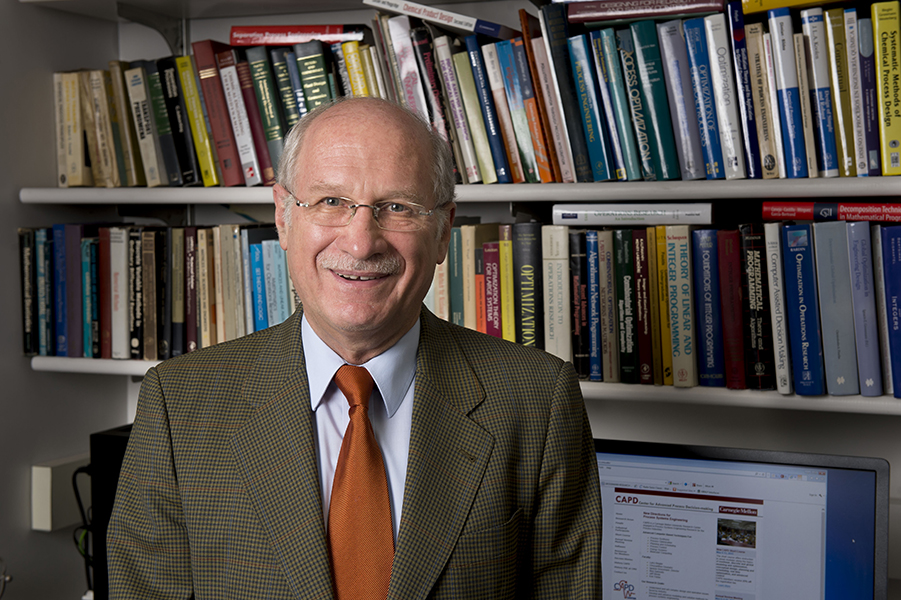

Ignacio Grossmann

Rudolph R. and Florence Dean University Professor

Chemical Engineering

Related news

Center for Advanced Process Decision-making

The Center for Advanced Process Decision-making (CAPD) provides an umbrella organization to give students the opportunity to interact with industry in the area of process systems engineering.